In today’s competitive manufacturing landscape, efficiency and safety are not optional — they are essential. Factories and industrial facilities constantly move raw materials, semi-finished goods, heavy equipment, and finished products across different floors and departments. Without the right equipment, this process can slow production, increase labor costs, and create serious safety hazards.

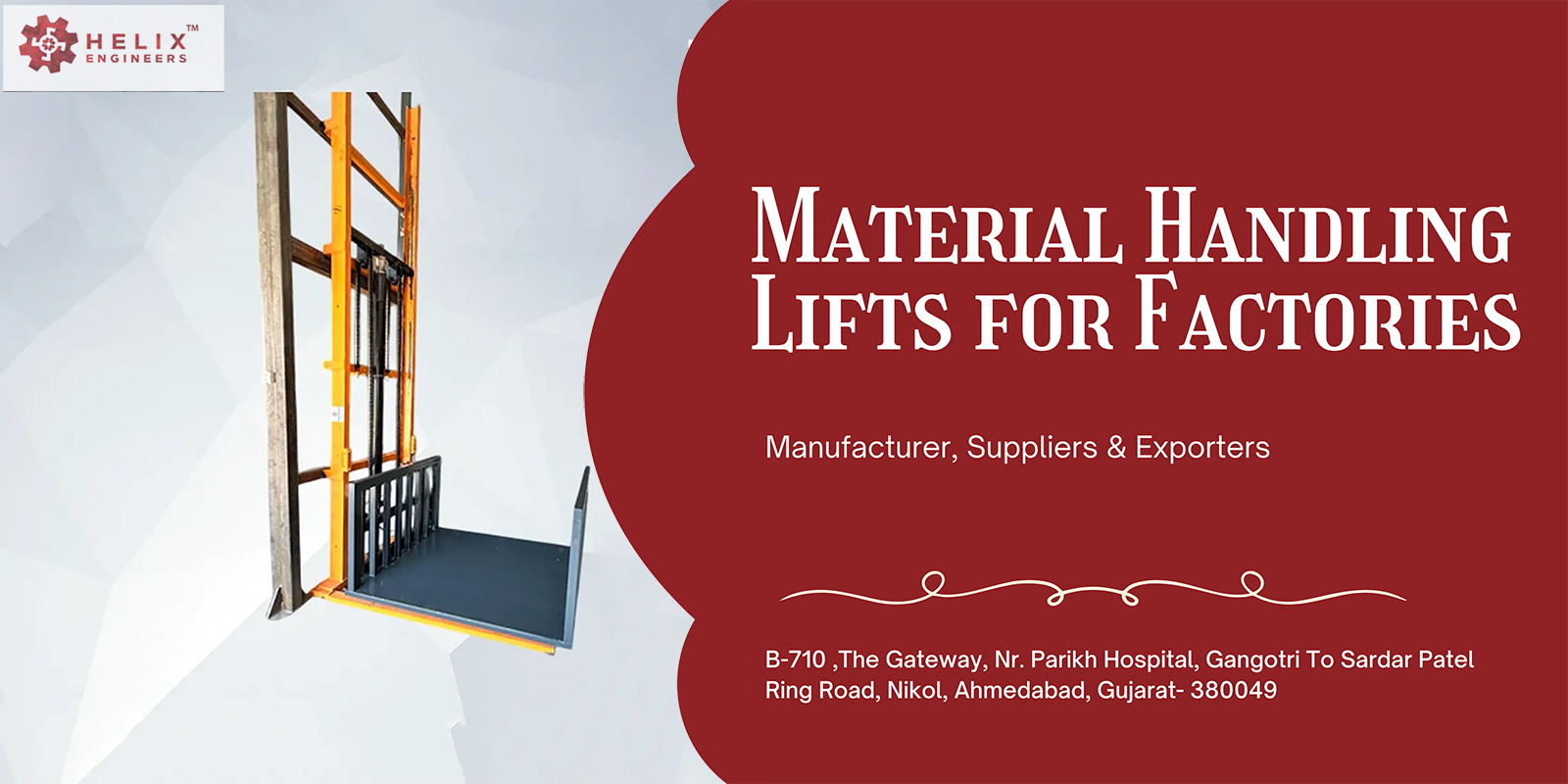

Material handling lifts are specialized lifting systems used in factories, warehouses, and industrial units to move goods between different heights or floors. Unlike passenger elevators, these lifts are specifically designed to carry materials, pallets, machinery parts, tools, and bulk goods.

Manual material movement consumes time and manpower. A goods lift streamlines the process by allowing quick vertical transportation of heavy loads, reducing delays in production.

Workplace injuries caused by lifting heavy loads are common in factories. Material handling lifts minimize:

Instead of assigning multiple workers to move materials manually, a lift system performs the task efficiently. This leads to:

Factories often struggle with limited floor space. Installing a vertical material handling lift allows better use of vertical space, eliminating the need for large ramps or excessive forklift movement.